evel measurement is a key requirement in many industries where accurate data on liquid levels is needed for purposes ranging from managing storage through to reporting. In water and wastewater treatment applications, where dozens of level devices may be used, a product that offers simple commissioning, reliable operation, fast delivery and easy maintenance offers tremendous customer value.

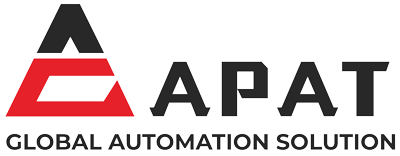

Developed in conjunction with our customers and drawing on ABB’s extensive experience in level measurement, the LST200 ultrasonic level transmitter offers a simple, smart and reliable level measurement solution. Featuring a modular design, the LST200 utilizes the latest developments in digital sensing technology, including built-in smart chip and an interface for upgrading with future modern data acquisition methods such as NB-IoT, offering the full benefits of digitalization for improved measurement and sharing of data.

FEATURES:

Easy to use

• Easy setup menu and clear backlight for easy configuration

• Easy installation, maintenance and upgrade with modular design

Smart and reliable

• Compact transmitter with real-time echo waveform display and diagnostic messages

• Reliable accuracy with temperature compensation (better than ±3mm or 0.25% of full span)

• Reliable and smart algorithm with noise filtering for challenging applications

• Reliable protection grade IP66/IP68 which is typical for water and wastewater industry

• Reliable electromagnetic compatibility (IEC CISPR standard) proved by independent laboratory testing

Technical specifications

Measurement

• Measurement range

0.35 to 8.00 m (13.78 to 314.96 in)

Note:

Operating conditions could attenuate the ultrasound, which may shorten the measurement range. Consult with ABB for applications involving bulk material, heavy vapor or dust, strong turbulence or foam.

• Beam angle

(@ -3 dB, full angle) : 10°

• Accuracy and Repeatability

±3 mm or 0.25% of full span, whichever is larger

Note:

Accuracy and stability are further ensured by algorithm including temperature compensation, GAP regulator and noise filter.

• Resolution

1 mm

• Update time

2 s

Electrical Data

• Terminals

Max. cable cross section: 1.5 mm2 (AWG 16)

• Power supply

LST200-Basic: 15 to 30 VDC.

LST200-LCD: 19 to 30 VDC.

Ripple: Maximum 5 %

• Power consumption

60mW to 600mW

• Analog output

Two-Wire output: 4 to 20 mA related to level/distance/volume/flow, full compensation for temperature effects

• Integrated LCD display (Optional)

Blue backlight, 6 mm height display with percentage bargraph

Simplified two-button programming with easy set up menu enables fast configuration

Real-time waveform

Diagnostics message

Totalized and actual flow indication

Language: English and Chinese

Mechanical Data

• Housing and sensor enclosure: PC (Polycarbonate)

Note: The chemical compatibility of the sensors must be checked

before installation.

• Dimensions

90 × 81 × 209 mm (3.56 × 3.19 × 8.24 in)

• Weight

680 g

• Cable entry

M20 × 1.5 threaded bore for cable gland, directly on housing

• Process xonnection

M56x3.0, length 35mm

Environmental Data

• Electromagnetic compatibility (EMC)

· IEC 61326-1 Table 2

· CISPR Class B

• Protect IP

IP66/67 according to EN 60529

IP68-rated up to 2 meters for 24 hours at room temperature

• Temperature

-30 to 60 °C (-22 to 140 ℉) , according to EN 60068-2-14

-20 to 60 °C (-4 to 140 ℉) for display

• Humidity

Relative humidity: up to 100 %

• Sensor Pressure

Measurement functional from -4 to 44 psi

(-0.25 to 3.0 bar)

• Vibration resistance

Random: according to EN 60068-2-64

Shock: IEC 60068-2-27

• Climate class

IEC 60068-2-38 Test Z/AD