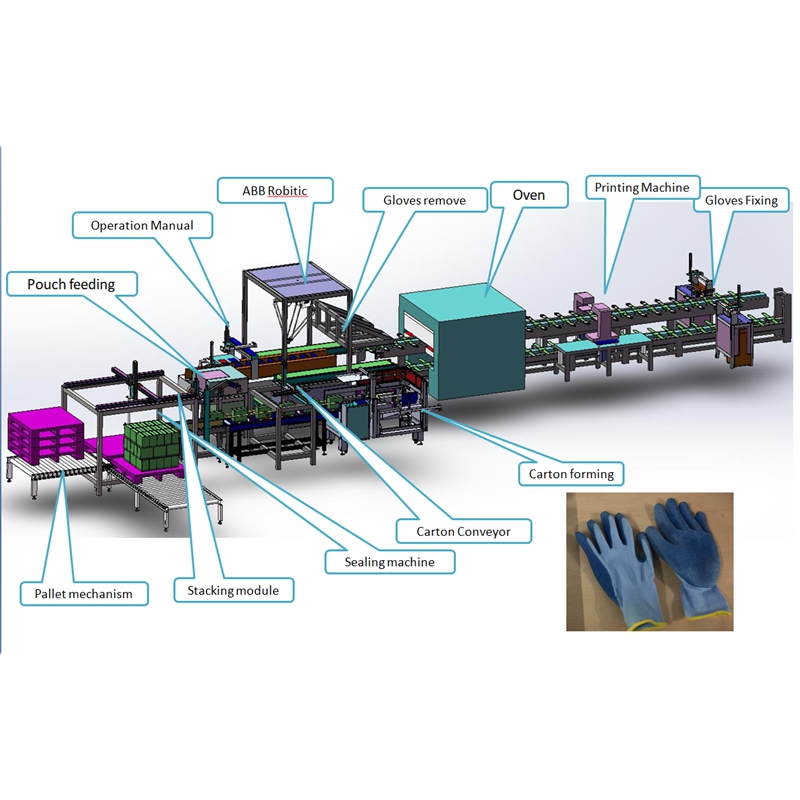

Work flow:

1.Fix gloves and printing

2.Conveyor delivery the gloves

3.Robotic with vision recognize front and back side and adjust to the right position

4.Automatically stacking and counting

5.Automatically put the instruction book

6.Automatically fill in pouch

7.Inspection

8.Automatically carton packing and sealing, and palletizing

Safty Design

1.All ac wiring positions are hard to reach by operators, and all connections are plugs and sockets, without external connectors.In normal use, the operator should not contact the ac.

2.The metal operating surface contacted by the operator is well grounded;

3. All the equipment used in the system is installed in the cabinet and fixed in a structural way to prevent people from falling and hurting;

4.During the test, the operating door will be locked to prevent misoperation and harm to human body;

5.The system has perfect emergency stop and fault protection mechanism.If the emergency stop button is pressed, the system will automatically cut off the control power supply and air source.The operation process is controlled by reliable safety relay to ensure fast and reliable response to abnormal conditions.

6.The equipment itself adopts multiple protective measures, including heat dissipation, ac air switch, wiring block with protective function, etc. The measuring circuit is isolated by photocoupling to ensure the safety of the measuring equipment.

7.Safety grating is installed around the equipment to ensure that the equipment can be stopped quickly by someone trespassing in the running state.