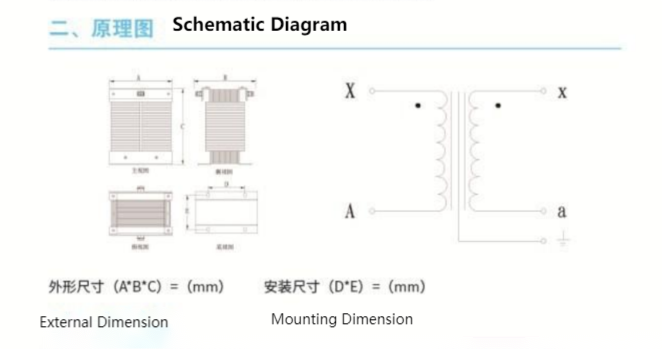

Structure Introduction

1、The transformer is divided into single-phase transformer, are E-type iron core dry type.

2、The core adopts high quality low loss cold rolled oriented silicon steel sheet, the main material for 0.3 and 0.35 thick H18, H14, H12, Z11 high quality silicon steel sheet, we according to the customer’s requirements and conditions of use, choose the most suitable material, so that the transformer performance design to achieve the best!

3、Coils are all wound with H-class enameled wire, tightly and evenly hooked, the appearance of the insulation layer is not wrapped, with excellent aesthetics, and has a better heat dissipation performance.

4、After assembling the transformer coil and iron core into one piece, it goes through the process of pre-baking, vacuum dipping paint and hot baking curing, and adopts H grade impregnating paint to make the transformer coil and iron core firmly combined together, which not only greatly reduces the noise of the operation but also ensures that the transformer can be operated safely and noiselessly under high temperature with very high heat-resistant grade.

5、Transformer core column part of the fasteners using non-magnetic materials, to ensure that the transformer has a

higher quality factor and lower temperature to ensure that has a good filtering effect.

6、Terminals: small power using Taiwan Mark terminal row, Japan TX terminals, beautiful appearance, has excellent pressure resistance, temperature resistance, flame retardant properties. High-power pro-quality copper.

7、Iron foot: the main use of CNC bending cold rolled plate, there are following five colors (gold), blue zinc (silver), white zinc (ivory), surface treatment (black) and other environmentally friendly plating can be selected.

8、The transformer and domestic similar products compared with the small size, light weight, beautiful appearance and other advantages, can be comparable with foreign famous brands.