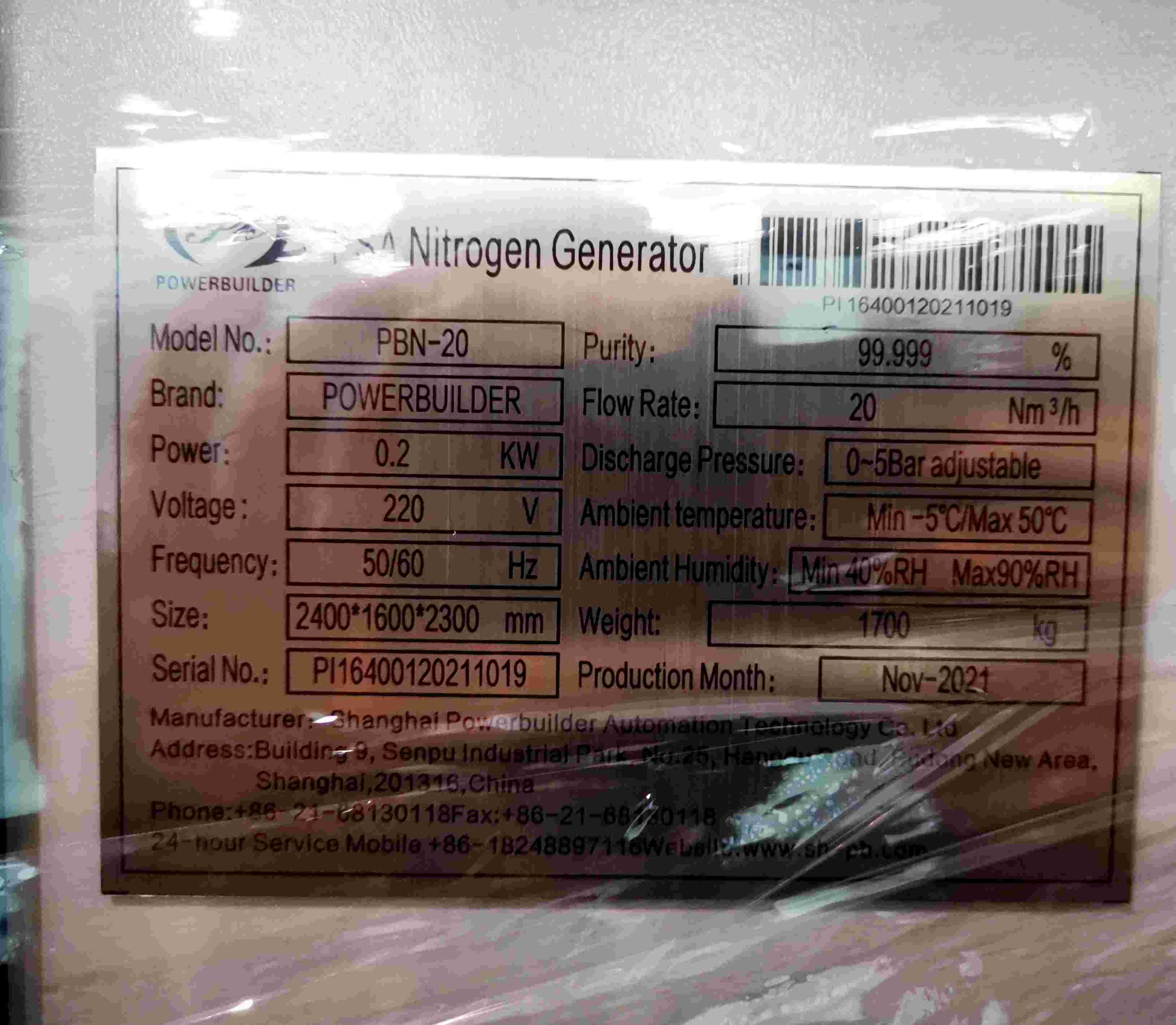

| PN3080 PSA Nitrogen Plant Technical Specification | ||||||

| lot | Item | Description /Specification | ||||

| 1 | Model/Place of Manufacture | PN3080 | ||||

| 2 | Nitrogen making principle | PSA Pressure swing adsorption PSA变压吸附(开放式结构) | ||||

| 3 | Application | Operation place | Indoor | |||

| Environment | Ambient temperature | Min -5℃/Max 50℃/ design temperature37℃ | ||||

| Ambient humidity | Min 40%RH Max90%RH | |||||

| 4 | Capacity | 80 | Nm3/hr | |||

| 5 | Nitrogen Gas Purity | ≥99.9 % Test at outlet of psa Nitrogen | ||||

| 6 | Nitrogen Purity Sensor | HT-TA261 1set | ||||

| 7 | Nitrogen Flowmeter | Japan SMC flowmeter 1 sets | ||||

| 8 | Inlet compress air pressure | 0.75 -0.99Mpa | ||||

| 9 | Inlet Oil Content | ≤0.001mg/m3 | ||||

| 10 | Residual dust | ≤0.01um | ||||

| 11 | Residual water | ≤0.069mg/m3 | ||||

| 12 | Air inlet atmospheric dew point | -15℃ | ||||

| 13 | Demand for clean compressed air | 4.93 | Nm3/min | Recommend Air compressor | 45Kw (6.5m3/min 10Bar ) or 30Kw (5.0m3/min 8Bar) | |

| 14 | Inlet Diameter | DN40 | ||||

| 15 | Outlet Diameter | DN25 | ||||

| 16 | Maximum inlet temperature | MAX 30 ℃ | ||||

| 17 | Allowable working pressure range | Min7.5Kgf / cm2 Max9.9Kgf / cm2 | ||||

| 18 | Carbon molecular sieve model/origin | CMS-240 | ||||

| 19 | The tower body pipe | 2 sets | ||||

| 20 | Air and nitrogen buffer tank | Piped storage tank | ||||

| 21 | Instrument Tank, silencer | PB Silencer ≤55dB(A) patent number:ZL 2015 2 0545860.3 | ||||

| 22 | Solenoid valve brand/origin | AirTAC | 7 sets | |||

| 23 | Pneumatic valve brand/origin | PB-Customized | 11 Sets (two for auto drain unqalified Gas) | |||

| 24 | Control System | Control Power Supply | 0.2kw/set 220V 50 HZ | |||

| PLC | Mitsubishi core integrated screen /or Siemens S7-200 Smart | |||||

| electrical box | built-in | 1 set | ||||

| touch screen | Mitsubishi core integrated screen/ MCGS | |||||

| 25 | size LxWxH (mm) / Weight:(Kg) | About:1800*1000*2300// 1200kg | ||||

| 26 | Price | 含税含运费 交期20天 | ||||

Working Principles for PSA Nitrogen Generator

Pressure swing adsorption(PSA)nitrogen generator is an automatic equipment that uses air as material,use carbon molecular sieve as adsorbent, pressure reduction desorption principle to adsorb oxygen from the air, thereby separating nitrogen.

Main Features for PSA Nitrogen Generator

- Raw material air is taken from nature. Nitrogen can be produced by supplying compressed air and power.

- Nitrogen purity can be adjusted conveniently and be produced by supplying compressed air

- The equipment is highly automated, produces gas quickly, and can be unattended. Nitrogen can be produced within 10-15 minutes of startup.

- The equipment process is simple, occupies a small area, consumes less energy and costs.

- Molecular sieves are filled by snowstorm method to avoid the pulverization of molecular sieves caused by avoid the pulverization of molecular sieves caused by high-pressure airflow impact and ensure the long-term use of molecular sieves.

- On-line inspection of imported analyzer with high access is simple, occupies a small area, consumes less energy,and costs.

Technical indicators

- Capacity Range : 2~2000Nm3/H

- Purity Range : 95%~99.9999%

- Outlet Pressure :0~6Bar or 0~ 8Bar

- Booster outlet pressure range : 10 to 200Bar

- Service Life 8-10 years as long as regular maintenance

Carbon Molecular Sieve

High quality,high density, compact spring loaded, top/bottom balance, protected by a dedicated pressure sensor.

We usually use CMS-240 for purity below 99.99%

And use CMS-260 for purity of 99.999% in one step .

Standard Features

- Siemens PLC

- Customized and improved domestic valves

- 7-inch LCD display

- Taiwan AirTAC solenoid valve

- Chengdu Jiuyin Nitrogen analyzer

- SMC flowmeter

- Professional brand molecular sieve

Optional Features

- Remote control system

- Better valve of brand Gemu, Burkert

- Dew point analyzer

- Import Molecular Sieve

- Italian ODE solenoid valve

-Applications-

- Application of SMT industry

- Semiconductor silicon industry application

Semiconductor and integrated circuit manufacturing process atmosphere protection, cleaning,chemical recovery,etc.

- Electronic components industry application

Selective welding, puring and encapsulation with nitrogen. Scientific nitrogen inert protection has proven to be an essential step in the successful production of high quality electronic components.

- Semiconductor packing industy application

Packaging, reduction, strage with nitrogen.

- Powder metallurgy, metal processing industry

Heat treatment industry application, Steel, iron, copper, aluminum products annealing, carbonization, high temperature furnace protection, Low temperature assembly and plasma cutting of metal parts.

- Chemical industry, advanced material industry application

Nitrogen is used to create oxygen – free atmosphere in chemical process, improve the safety of production process, fluid transmission power source, etc: It can be used for nitrogen purging of pipes and vessels in the system, filling nitrogen Storage tank, gas displacement, leak detection, combustible gas protection, chemical reaction agitation, chemical fiber production protection, also used in diesel hydrogenation and catalytic reforming.

- Oil and gas industry

Oil refining, container machine pipeline nitrogen-filled purge box leak detection, nitrogen injection oil recovery.

- Food and medicine industry Application

Food Packaging: Enhance packaging materials to improve food safety, extend shelf life, and prevent contamination. Develop innovative packaging solutions such as active packaging that incorporates antimicrobial agents or oxygen scavengers to preserve food freshness.

Food Preservation: Explore advanced preservation techniques like modified atmosphere packaging (MAP) to control the gas composition surrounding food products. Optimize MAP systems to maintain optimal conditions for specific food types, extending their shelf life while preserving quality and taste.

Food Storage: Utilize smart storage solutions that employ temperature and humidity control mechanisms to ensure optimal storage conditions. Implement IoT (Internet of Things) technology to monitor and regulate storage environments, minimizing spoilage and reducing food waste.

Configurable Sterilization Filter: Develop customizable sterilization filters capable of efficiently removing pathogens and contaminants from the air or liquid streams used in food processing and packaging. These filters should be adaptable to different manufacturing processes and enable easy maintenance and replacement.

Food Drying and Sterilization: Implement advanced drying and sterilization methods such as vacuum drying, freeze-drying, or microwave sterilization to improve efficiency and maintain food quality. Optimize these processes to minimize energy consumption and reduce processing time while preserving nutritional value.

Medicine Packaging: Enhance pharmaceutical packaging materials to ensure product integrity, stability, and protection against external factors like moisture, light, and oxygen. Develop tamper-evident packaging solutions to prevent unauthorized access and counterfeiting.

Medical Replacement Gas: Improve the purity and reliability of replacement gases used in medical applications. Ensure adherence to stringent quality control standards and optimize gas storage and delivery systems for safe and efficient use.

Medicine Delivery Atmosphere: Develop controlled atmosphere environments for medicine storage and delivery, maintaining specific temperature and humidity conditions to preserve medication efficacy. Implement intelligent monitoring systems to track storage conditions and enable timely interventions if deviations occur.